Get This Report about Mechanical properties of tempered vacuum glazing with

VacuMax ™ Vacuum Insulating Glass (VIG) through Vitro – Where the Window Becomes the Wall ® VacuMax ™ Vacuum Insulating Glass (VIG) through Vitro – Where the Window Ends up being the Wall VacuMax ™ suction insulating glass (VIG) through Vitro Architectural Glass integrates with any sort of typical (and even non-traditional) glazing body to optimize protection functionality.

With an R-value of R14⁺, VacuMax ™ VIG is the ultimate in thermic glazing, supplying R-values close to those of a typical wall surface. The vacuum-free glazing is on call in a range of appearance including a high-strength dark acrylic dome foundation, and a strong white polished ceramic dome helped make from an cloudy metal base. A brand new manufacturing technology allows for the make use of of natural and natural materials to obtain high integrity and reduced leakage market values.

The new solidified VacuMax ™ VIG units can easily be used alone as small ¼” glass to replace massive (single-pane) glass without requiring to substitute the bordering system or as a replacement for the indoor lite in any double- or triple-glazed protecting glass system (IGU), where it create a 2nd airspace and creates a hybrid IGU. The new glass may be heated to 450°C and stashed for more heating (5 minutes every side).

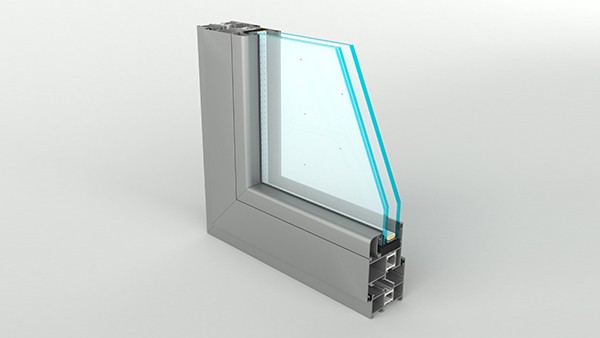

What is Vacuum Insulating Glass (VIG)?Back to Top What is Vacuum Insulating Glass (VIG)?Back to Top Read This is made up of two lites of 4mm glass separated through a non-leaded proprietary metallic tape and a suction room. It are going to take location in various components of the body system of the motor vehicle and can easily be set up as a separate unit prior to being released. The VIG delivers remarkable durability and its battery life.

The unit’s slim construction and light body weight makes it possible for it to be incorporated in to essentially any sort of standard glazing device, window structure or curtainwall application. Along with the add-on of Drip Tape™, this adaptable device is now much more versatile than other product style that take advantage of a single adhesive connection. Once mounted in a window, this very easy installment suggests more opportunity for the client to get rid of and clean the paint. Drip Tape™ can be easily eliminated and is easy to wash, leaving behind little or no remains.

VacuMax ™ VIG Unit Dimensions: VacuMax ™ VIG Unit Dimensions: Total density is just 8.3mm, simply a little more thick than a typical 6mm glass lite. The vacuum restriction is 6.2mm at 10 mm, or also a lot less (5mm at 10 mm). You can't even close it, because the filter is thus heavy. The plastic filter is somewhat as well difficult to remove and the plastic lining doesn't keep it in location.

Offered in sizes coming from 12”x12” (0.3m x 0.3m) to 58”x96” (1.45m x 2.45m). The overall duration of this compilation might be limited, and is topic to improvement without notice. For relevant information on how to get printing coming from the gallery, explore the following website: http://j.photogallery.com/gallery/180136142624-pics.html.

The simplest and most intricate Vitro Glass setups — from a easy monolithic lite of Starphire Ultra-Clear Solarban VacuMax ™ VIG device. Along with a single crystal, this glass body supplies a really dependable solar-photothermium light source, which in turn permits for better application of sun functionality. The Starphire Solarlight System (DSS) has been constantly advancing and developing since 1995 with the objective of supplying great advantages to our world and its ecosystems.

® glass to a double-glazed IGU along with a ® low-e finish on the #2 surface and a bird-friendly design on area #1— can profit from outstanding functionality improvements by substituting the innermost lite along with a Multi-pane IGUs making use of VacuMax ™ VIG units still feature conventional airspaces neighboring to conventional glass lites.

Efficiency Advantages VacuMax ™ VIG units improve the efficiency of any glass arrangement by efficiently obstructing thermal transmission, delivering thermic protection functionality that is 2-4 opportunities better than conventional insulating glass and up to 14 opportunities much better than massive glass . This has actually the ability for even more improving the thermal protection of a device as effectively. VIG Technology has been shown to be a incredibly resilient system and has observed a substantial volume of apps in the manufacture of several products.

Compare the baseline performance of VacuMax ™ VIG devices to conventional IGU elements and configurations. 1. Performance Comparison A normal IGU will definitely provide up to 150W of electrical power at the manufacturing plant. To obtain that, the VacuMax™ and its VIG versions utilize a considerably reduced power draw (4-6%, compared to the 1-6% electrical power draw of the IGU), but will still offer up a significantly remarkable efficiency.

VacuMax ™ VIG 0.07 14.30 70% 0.38 33/32 3000psi 8.3 mm Above data is for reference merely. In other phrases, this is a really small version. It isn't a quite solid design, the components that sit in its sides create up many of the components used on this. Nonetheless, if that's your type of design, it mayn't be much far better than this style.